Shrink film machines are indispensable tools in various industries, especially in packaging, where they play a crucial role in ensuring that products are securely wrapped and protected. Whether you’re in the food industry, pharmaceuticals, retail, or manufacturing, understanding shrink film machines is essential if you’re looking to enhance your packaging process. In this complete buyer’s guide, we will delve into what shrink film machines are, how they work, and the factors to consider when purchasing one.

What Is a Shrink Film Machine?

A shrink film machine is a device designed to apply a thin layer of plastic film, known as shrink film, around a product. This film is then heated to shrink tightly around the item, offering protection and giving it a neat, professional appearance. Shrink film machines come in different types and sizes to cater to various business needs, from small operations to large-scale industrial packaging.

Types of Shrink Film Machines

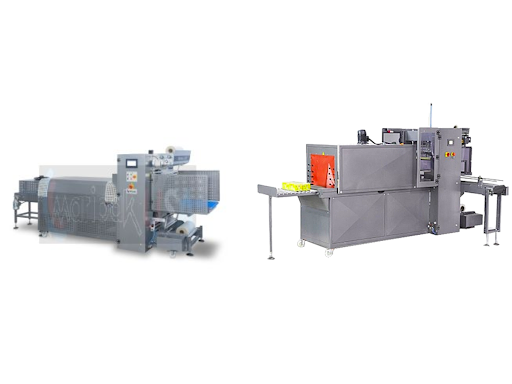

There are two main types of shrink film machines: manual and automatic. Each has its advantages and is suitable for different production environments.

- Manual Shrink Film Machines: These are generally used for small-scale operations or businesses just starting out. They require the operator to manually place the product on a conveyor belt or inside the machine, and the operator also controls the heating process. While manual machines are less expensive, they require more labor and are not as efficient as automatic machines.

- Automatic Shrink Film Machines: These machines are designed for high-volume production. They automatically feed the product through the machine, apply the shrink film, and seal it with minimal human intervention. Automatic machines are faster and more efficient than manual ones and are perfect for large-scale operations where speed and consistency are critical.

Factors to Consider When Buying a Shrink Film Machine

When it comes to purchasing a shrink film machine, there are several important factors you need to take into consideration. These factors will help you choose a machine that fits your business needs and budget.

1. Type of Shrink Film

There are different types of shrink film materials available, such as PVC, polyethylene, and polypropylene. The type of film you choose will depend on the type of products you are packaging. Some films are more durable, while others are more cost-effective but may not offer the same level of protection.

- PVC Shrink Film: Ideal for retail products and often used for small packaging, as it offers a clean, clear finish.

- Polyethylene Shrink Film: Often used for larger or heavier products, as it offers better protection during transport.

- Polypropylene Shrink Film: Known for its strength and durability, often used for food and medical packaging.

Make sure the shrink film machine you choose is compatible with the type of shrink film you plan to use.

2. Machine Capacity and Size

The size and capacity of the shrink film machine should match your production needs. If you run a small operation or your product range is diverse, a smaller, manual shrink wrap machine might suffice. However, if you require high-speed production and need to package large quantities of items quickly, an automatic shrink film machine with a larger capacity is more suitable.

- Small-Scale Machines: Best for businesses with lower production volumes or those that handle a wide variety of products.

- Industrial-Scale Machines: Suitable for high-volume packaging and capable of running continuously for long hours.

3. Budget and Cost

Shrink film machines come in a wide range of prices, depending on the type, features, and capacity. While manual machines are more affordable, automatic machines can be a larger upfront investment but may save on labor costs and time in the long run. It’s important to assess your production goals and budget to choose a machine that provides the best value for your needs.

4. Ease of Use and Maintenance

The ease of use and maintenance should also be a key consideration when purchasing a shrink film machine. Some machines come with user-friendly interfaces, automatic adjustments, and intuitive controls that make the process much easier, especially for new users. Additionally, consider the availability of spare parts, customer service, and the machine’s reliability in terms of longevity.

Conclusion

Investing in an automatic shrink packing machine is a great way to enhance your packaging process, protect your products, and ensure a professional presentation. By considering factors like film type, machine capacity, budget, and ease of use, you can the right shrink film machine for your business needs. Whether you’re a small business or a large-scale operation, the right shrink film machine will increase efficiency, save on labor costs, and improve your overall packaging quality. The key to successful investment lies in selecting a machine that aligns with your specific production requirements, ensuring that your products are packaged securely and efficiently.