In today’s fast-paced manufacturing and packaging industries, efficiency and speed are essential for maintaining a competitive edge. One of the most effective ways companies achieve higher productivity while reducing costs is by utilizing automatic shrink packing machines. These machines are revolutionizing packaging processes by providing quicker, more efficient solutions for wrapping products in shrink film. From small consumer goods to large industrial items, shrink wrapping plays a pivotal role in securing and protecting products for transportation and storage. This blog delves into how automatic shrink-packing machines streamline operations, ensuring maximum output and contributing to overall business success.

What is an Automatic Shrink Packing Machine?

An Overview of Shrink Packaging

Shrink packaging involves wrapping products with a heat-sensitive plastic film that conforms tightly around the item when heated. This process not only secures the product but also provides a protective layer against dust, dirt, moisture, and tampering. The film used for shrink wrapping is often made from materials like polyolefin, PVC, or polyethylene, depending on the product’s requirements.

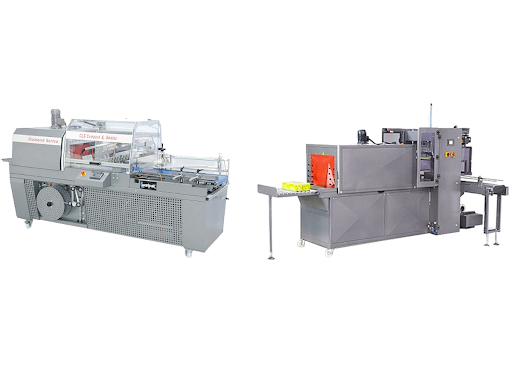

An automatic shrink packing machine automates the process of wrapping products in shrink film. These machines are designed to handle a wide range of product sizes and types, making them a versatile solution for various industries, including food and beverage, pharmaceuticals, electronics, and consumer goods. The automation of the shrink wrapping process leads to faster production speeds, more consistent packaging quality, and less human error.

Key Benefits of Using Automatic Shrink Packing Machines

Increased Efficiency and Speed

One of the primary reasons businesses invest in automatic shrink packing machines is the significant boost in efficiency and speed they provide. Manual shrink wrapping can be slow and labor-intensive, often requiring multiple workers to complete the task. Automatic machines, however, streamline this process, allowing businesses to package products at a much faster rate.

With automated systems, products are fed into the machine, where they are wrapped and sealed with minimal intervention. The machine then moves the wrapped product along the production line to the next step in the packaging or shipping process. This increase in speed allows businesses to meet higher production demands, reduce wait times, and improve overall operational efficiency.

Consistency and Precision

Another major advantage of automatic shrink packing machines is the consistency they provide in packaging. Manual shrink wrapping often leads to variations in how tightly or evenly the film is applied to each product. This inconsistency can result in waste or products that are improperly sealed.

Automatic machines, on the other hand, ensure precise, uniform wrapping every time. This consistency helps businesses maintain a high standard of quality and reduces the risk of defects in the finished product. Whether you are packaging thousands of items daily or a small batch, automatic shrink wrapping guarantees that each product is securely and accurately wrapped.

Cost Savings

Investing in an automatic shrink packing machine can lead to significant cost savings in the long run. Although the initial investment might seem high, businesses often recoup their costs quickly due to reduced labor requirements, improved efficiency, and decreased material waste.

By automating the shrink wrapping process, companies can minimize the need for manual labor, reducing staffing costs. Additionally, these machines often come with built-in features that help reduce the amount of shrink film used, ensuring that every inch of material is utilized efficiently. This reduction in film waste further lowers operational costs and increases profit margins.

Applications of Automatic Shrink Packing Machines

Food and Beverage Industry

In the food and beverage industry, packaging is a critical component in maintaining product quality. Shrink wrap packaging machines are widely used for packaging items such as bottled drinks, snacks, and frozen food. The shrink wrapping process ensures that these products are sealed tightly, preventing contamination and extending shelf life.

Pharmaceuticals and Healthcare

For pharmaceutical and healthcare products, secure packaging is essential. Shrink wrapping helps protect products such as medicine bottles, medical devices, and health supplements from tampering and damage. It also ensures that these products meet regulatory requirements for safety and packaging standards.

E-commerce and Retail

With the rise of e-commerce, efficient packaging has become more important than ever. Automatic shrink packing machines are ideal for packaging products that are shipped directly to consumers. They help businesses efficiently pack and ship a wide variety of products, from electronics to clothing, with added protection during transit.

Conclusion

Automatic shrink packing machines have become an invaluable asset to businesses across various industries. By streamlining packaging operations, these machines provide a host of benefits, including increased efficiency, consistency, cost savings, and enhanced product protection. Their versatility and ability to handle a wide range of products make them an indispensable tool in today’s fast-paced manufacturing and packaging world.